The Materials We Use

When selecting a material to launch a collection, we carefully consider the key design aspects and price point we are looking to achieve.

Our hardware is made of one of three metals – brass, zamac or aluminium – the natural tone of these materials are not reflected in the end product.

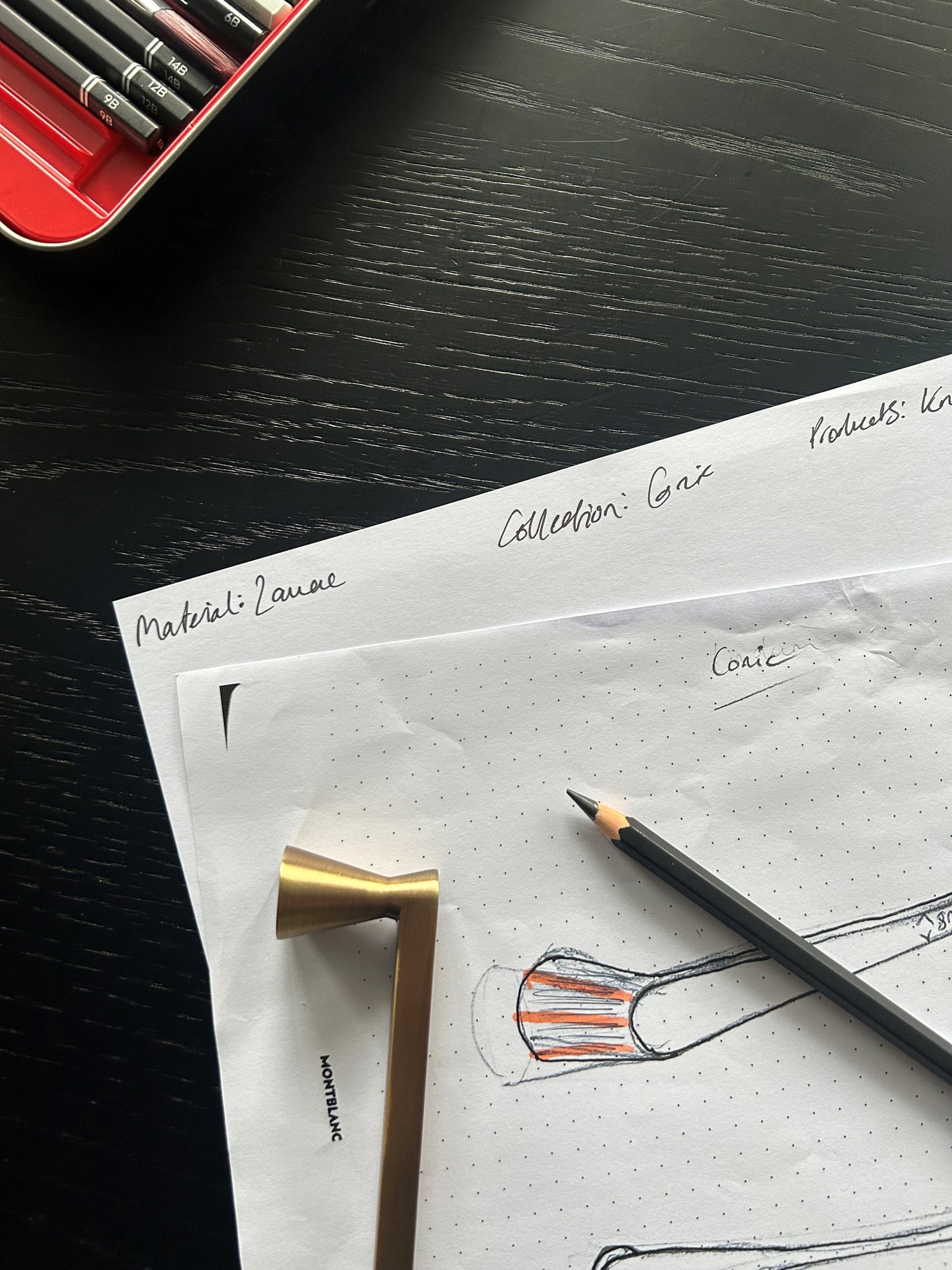

Brass Hardware

The durability, corrosion resistance, and low melting point of brass make it a favoured choice for detailed and intricate cabinet hardware. Composed primarily of copper and zinc alloys, brass is the heaviest material among the three we use. Its high copper content typically results in a higher price point. The Belgravia Knob & Fitzrovia Pull Handle is an example of where perfect refinement of each angle is achieved through the use of brass.

Zamac Hardware

Often used for both interior and exterior hardware due to its versatility when designing products, durability in high use areas, consistency of finish and corrosion resistance. Zamac is a zinc alloy composition of aluminium, magnesium, copper and zinc, and due to its lower percentage of copper than that found in brass, it's usually more affordable. It is somewhat lighter than Brass when compared next to each other. The Barrington Cup Handle is a design staple for the team at Hendel & Hendel.

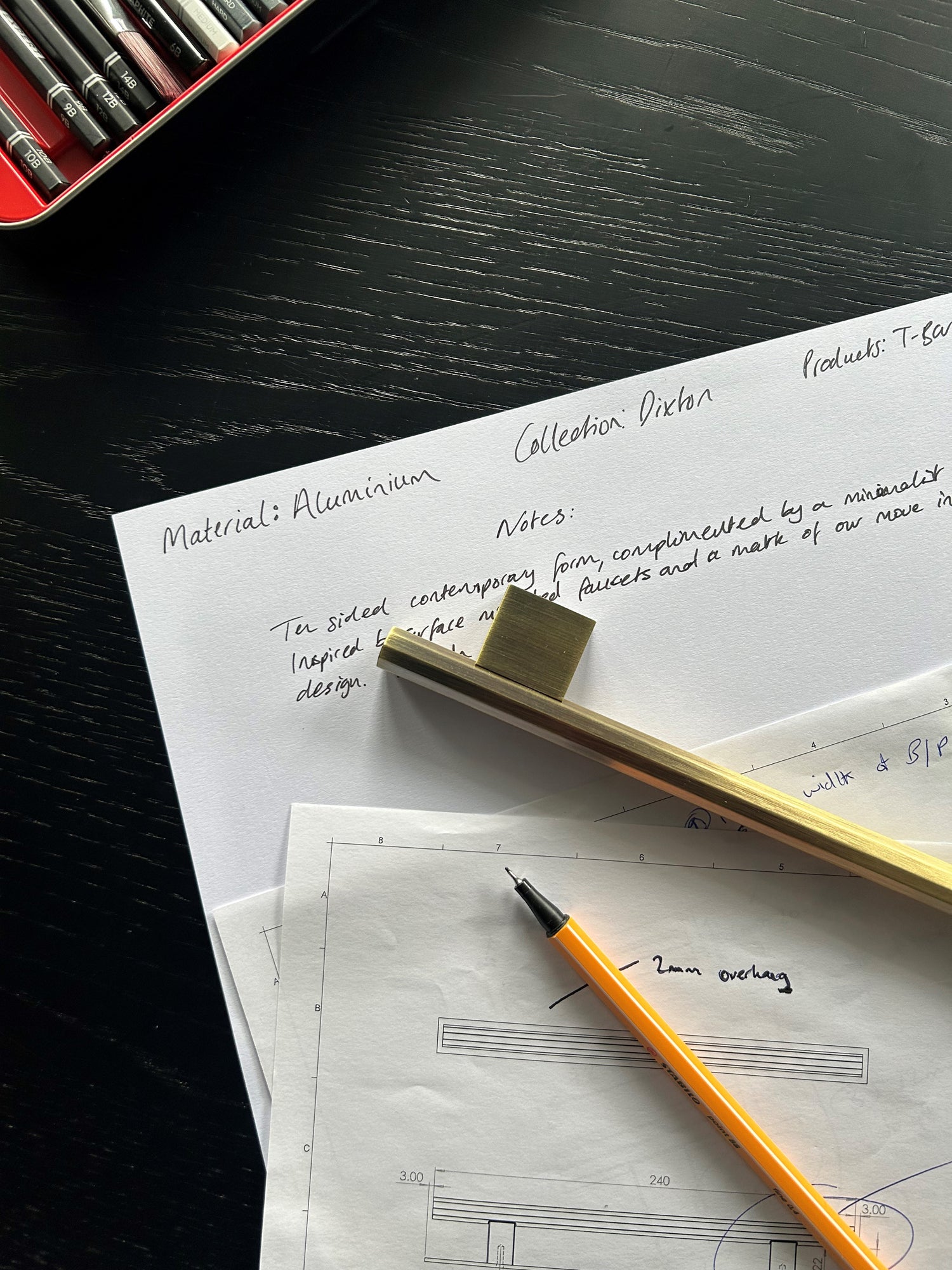

Aluminium Hardware

With its significantly lower density than other metals and corrosion resistance, aluminium is a perfect cost-effective material choice for cabinet hardware. The properties allow for continuous patterns such as the Dixton Pull Handle. It is lighter when held loose in the hand however the finishing and design of the product isn’t impacted by this.